Research stories

From student to astronaut: developing the skills to understand the world

Postsecondary students and postdoctoral researchers play a crucial role in the Canadian research ecosystem by pushing back the boundaries of knowledge.

| Image, title and teaser | Location | Sector/Industry | Media type |

|---|---|---|---|

Advancing Reproductive Efficiency & Stress Management in Beef Heifers The primary goal of a cow-calf operation is to produce one calf per cow per year. However, the journey to achieving this reproductive success is fraught with challenges influenced by a variety of factors, including genetics, nutritional status, and stress, each playing a crucial role in the performance of heifers. |

Alberta | Alberta, Agriculture and primary food production, Biological Systems and Functions, College and Community Innovation | Désirée Gellatly |

uOttawa scientists develop novel radiotracer for earlier detection of disease Turns out a spoonful of sugar helps the medicine go down - and lights up a PET scan. |

Ontario | Ontario, Advancement of knowledge, Chemistry, Discovery Research, Research Training and Talent Development | |

Physically impaired primates find ways to modify their behaviours to compensate for their disabilities, according to Concordia researchers Primates show a remarkable ability to modify their behaviours to accommodate their physical disabilities and impairments according to a new literature review by Concordia researchers. |

Quebec | Quebec, Evolution and Ecology, Research Training and Talent Development | |

Efficiency of plants used for bioretention not impaired by road salt The salt used to de-ice our roads does not reduce the effectiveness of the plants used in bioretention areas, according to a new study by Henry Beral, a Ph.D. student at the Université de Montréal. |

Quebec | Quebec, Environment, Evolution and Ecology, Discovery Research, Research Training and Talent Development | Henry Beral, Jacques Brisson, Danielle Dagenais |

New deep learning AI tool helps ecologists monitor rare birds through their songs Researchers at the Université de Moncton have developed a new deep learning artificial intelligence tool that generates life-like birdsongs to train bird identification tools, helping ecologists to monitor rare species in the wild. |

New Brunswick | New Brunswick, Environment, Evolution and Ecology, Research Training and Talent Development | Nicolas Lecomte, Sylvain Christin |

Rendering a winter wonderland As snow flurries mark the beginning of winter, a team of University of Waterloo researchers have created a new model featuring the white stuff that can be applied to better understand the impact of climate change. |

Ontario | Ontario, Information and communication services, Computer Science, Discovery Research, Research Training and Talent Development | Gladimir Baranoski, Petri Varsa |

Protecting communities from toxic mine waste Imagine an abandoned mine site, surrounded by dead trees and dotted with dark, red ponds with no signs of aquatic life. |

Ontario | Ontario, Commercial services, Environment, Geosciences, Discovery Research, Research Partnerships, Research Training and Talent Development | Aria Zhang, David Blowes, Carol Ptacek, Jeff Bain |

Indigenous student internships help build community This year, students in three different programs at Saskatchewan Polytechnic were awarded applied research Indigenous student internships. |

Saskatchewan | Saskatchewan, Health, education and social services, Biological Systems and Functions, College and Community Innovation, Research Training and Talent Development | Chanelle Gaudet, Kimberly Roberts, Dakota Schaffer |

Urbanization and climate change are putting a squeeze on mammals Larger animals like deer and moose are most affected as concrete replaces green space and cities get warmer and drier, researchers find. |

Alberta | Alberta, Environment, Evolution and Ecology, Discovery Research | Colleen Cassady St. Clair |

Custom-built pipette station: a vision for increasing lab accessibility Dr. Michael Babechuk is a geochemist in the Department of Earth Sciences at Memorial University of Newfoundland and Labrador. |

Newfoundland and Labrador | Newfoundland and Labrador, Advancement of knowledge, Geosciences, Discovery Research, Research Training and Talent Development | Michael Babechuk, Gabriel Sindol |

Discovery is about time and flexibility The Natural Sciences and Engineering Research Council of Canada (NSERC) believes in backing people with bold, promising ideas and giving them the freedom to explore when their research points them in exciting, unexpected directions. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research | John Smol |

Yoshua Bengio - Gerhard Herzberg Canada Gold Medal Few people have influenced theoretical and empirical progress on deep learning as much as Yoshua Bengio. |

Quebec | Quebec, Information and communication services, Computer Science, Discovery Research, Prizes | Yoshua Bengio |

Cathleen Crudden - NSERC John C. Polanyi Award Dr. Cathleen Crudden is a world-leading scientist whose research on the use of organic coatings to modify metal surfaces has garnered international recognition. |

Ontario | Ontario, Advancement of knowledge, Chemistry, Discovery Research, Prizes | Cathleen Crudden |

C20/20 Innovation Hub - Brockhouse Canada Prize For more than a decade, a dedicated team of scientists, engineers and clinicians have worked together to develop new biomaterials—and ultimately new therapies—for the nearly five million Canadians who suffer from impaired vision health. |

Ontario | Ontario, Health, education and social services, Materials and Chemical Engineering, Discovery Research, Prizes, Research Partnerships | Heather Sheardown, Todd Hoare, Judith West-Mays, Lyndon Jones, Varun Chaudhary, David Wong |

Peter Vanrolleghem - NSERC Donna Strickland Prize As climate changes produce more violent storms that damage urban infrastructure, optimal management of urban wastewater during heavy rainfall is becoming increasingly important. |

Quebec | Quebec, Environment, Civil, Industrial and Systems Engineering, Discovery Research, Prizes, Research Partnerships | Peter Vanrolleghem |

Michael Organ - Synergy Award for Innovation The speed with which this partnership achieved success played a key part in helping the world begin to move again after the first complete lockdown and laid the foundation for an enduring and impactful partnership for the future. |

Ontario | Ontario, Manufacturing processes and products, Chemistry, Prizes, Research Partnerships | Michael Organ |

Beth Parker - Synergy Award for Innovation Guelph is one of the largest cities in Canada that is totally dependent on groundwater for drinking water. Unfortunately, threats of contamination, climate change and a rising demand from Guelph and its neighbours are putting the sustainability of their shared aquifer at risk. |

Ontario | Ontario, Environment, Geosciences, Prizes, Research Partnerships | Beth Parker |

Allen Curry - Synergy Award for Innovation NB Power partnered with Professor Allen Curry and the Canadian Rivers Institute academic team to launch the Mactaquac Aquatic Ecosystem Study (MAES), a whole-river study of the Wolastoq (Saint John River), to develop new knowledge about the river ecosystem. |

New Brunswick | New Brunswick, Environment, Evolution and Ecology, Prizes, Research Partnerships | Allen Curry |

Guillaume Caron, Léo Charest and Dominic Lanteigne - Synergy Award for Innovation Air-pollutant emissions are a major issue for society, and wood-burning appliances are one of the main sources of fine particulates in the atmosphere. |

Quebec | Quebec, Manufacturing processes and products, Mechanical Engineering, College and Community Innovation, Prizes, Research Partnerships | Guillaume Caron, Léo Charest and Dominic Lanteigne |

Amanda Bates - Arthur B. McDonald Fellowships Oceans are being impacted by human activities and species are disappearing and migrating to different regions in response, altering existing natural systems. |

British Columbia | British Columbia, Advancement of knowledge, Evolution and Ecology, Discovery Research, Prizes | Amanda Bates |

Nicolas Cowan- Arthur B. McDonald Fellowships Astronomers have discovered thousands of planets orbiting stars millions of lightyears away, most of which look nothing like the worlds in our solar system. |

Quebec | Quebec, Environment, Physics, Discovery Research, Prizes | Nicolas Cowan |

Foutse Khomh - Arthur B. McDonald Fellowships The widespread impacts of artificial intelligence (AI) and machine learning (ML) have spurred calls for governance to ensure that AI applications are safe, dependable, fair, accountable, and transparent, and that they respect privacy. |

Quebec | Quebec, Information and communication services, Computer Science, Discovery Research, Prizes | Foutse Khomh |

Karen Maxwell - Arthur B. McDonald Fellowships Dr. Karen Maxwell is an internationally renowned expert in phage biology and a leading scientist who has had an undeniable impact on this cutting-edge field. |

Ontario | Ontario, Advancement of knowledge, Genes, Cells and Molecules, Discovery Research, Prizes | Karen Maxwell |

Chelsea Rochman - Arthur B. McDonald Fellowships Dr. Chelsea Rochman is a pioneer in the research on plastic pollution in aquatic habitats. Her work aims to understand how microplastics move through organisms and within food webs. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research, Prizes | Chelsea Rochman |

Mark Schmidt - Arthur B. McDonald Fellowships Dr. Mark Schmidt is an expert in machine learning (ML) whose research focuses on making ML faster and more user-friendly so it can become more broadly accessible. |

British Columbia | British Columbia, Information and communication services, Computer Science, Discovery Research, Prizes | Mark Schmidt |

Researchers use the James Webb Space Telescope to view growing “baby galaxy” Answering the question of how galaxies form and grow over time has been a driving reason for the construction of the James Webb Space Telescope (JWST). |

Nova Scotia | Nova Scotia, Advancement of knowledge, Physics, Discovery Research | Marcin Sawicki |

New rivers in the North? Scientists identify how the dissection of Arctic landscapes is changing with accelerating climate change New research co-led by Simon Fraser University and the University of British Columbia shows that amplified global warming in the Canadian High Arctic drove a profound shift in the structure of a river network carved into a permafrost landscape in only 60 years. |

British Columbia | British Columbia, Advancement of knowledge, Geosciences, Discovery Research | Shawn Chartrand, Mark Jellinek |

Space training program at USask launched many careers Jarle Steinberg wants to walk on the moon. It just might happen. |

Saskatchewan | Saskatchewan, Advancement of knowledge, Physics, Research Training and Talent Development | Jarle Steinberg, Kathryn McWilliams, Liam Graham |

Healing power of light: University of Ottawa team advances clear vision for eye repair With potential to impact millions, study finds that biomimetic materials pulsed with low-energy blue light can reshape damaged corneas, including thickening the tissue. |

Ontario, Quebec | Ontario, Quebec, Advancement of knowledge, Materials and Chemical Engineering, Discovery Research | Emilio Alarcon, Marcelo Muñoz, Aidan MacAdam, May Griffith, Isabelle Brunette |

Demystifying the work of research professionals The research professionals* who work in scientific laboratories perform a variety of tasks that involve all of their activities, such as supporting principal investigators, supervising students, organizing daily workloads and managing budgets |

Quebec | Quebec, Health, education and social services, Physics, Research Training and Talent Development | Anne-Sophie Poulin-Girard, Mireille Quémener |

UBCO researchers recover vital resources from wastewater sludge New technique can extract and recycle phosphorous from municipal waste |

British Columbia | British Columbia, Commercial services, Civil, Industrial and Systems Engineering, Research Partnerships, Research Training and Talent Development | Huan Liu, Cigdem Eskicioglu |

Ketone supplements worsen performance in trained endurance athletes, researchers find Kinesiologists at McMaster University have found ketone supplements, used by some athletes hoping to cross the finish line faster, may in fact worsen performance. |

Ontario | Ontario, Advancement of knowledge, Biological Systems and Functions, Discovery Research, Research Training and Talent Development | Martin Gibala, Devin McCarthy |

Rain gardens could save salmon from toxic tire chemicals Specially designed gardens could reduce the amount of a toxic chemical associated with tires entering our waterways by more than 90 per cent, new research shows. |

British Columbia | British Columbia, Water, Civil, Industrial and Systems Engineering, Discovery Research, Research Training and Talent Development | Timothy Rodgers, Rachel Scholes |

Sault College students collaborate with Boniferro Mill Works on applied research project Representatives from Sault College recently completed a successful College and Community Innovation (CCI) program applied research project in partnership with Boniferro Mill Works, a hardwood sawmill located in Sault Ste. Marie, Ontario. |

Ontario | Ontario, Manufacturing processes and products, Electrical and Computer Engineering | |

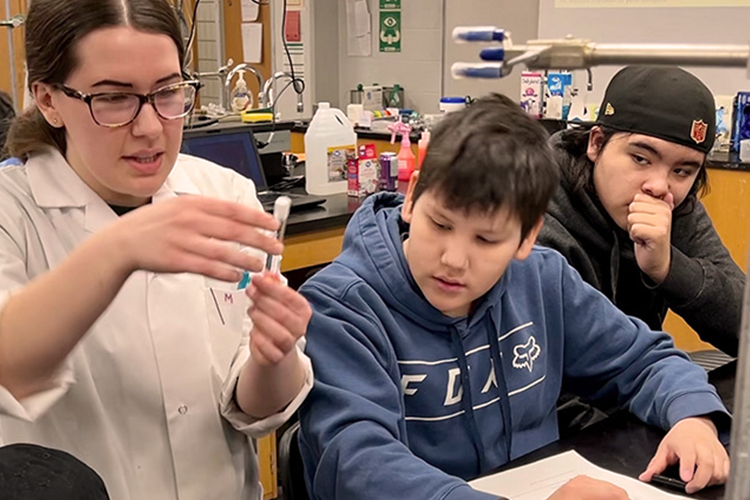

USask graduate student provides STEM experience for Indigenous elementary students As a Natural Sciences and Engineering Research Council of Canada (NSERC) Indigenous Student Ambassador at the University of Saskatchewan (USask), Morgan Fleming is creating opportunities for Indigenous students to engage in science. |

Saskatchewan | Saskatchewan, Science promotion, Science Promotion, Research Training and Talent Development | Morgan Fleming |

Agro-waste could be the solution to a cleaner water supply in Saskatchewan, says USask researcher Securing a safe water supply for Earth’s growing population is a global goal that is reflected in the long-term sustainability plans of almost every nation. |

Saskatchewan | Saskatchewan, Advancement of knowledge, Chemistry, Discovery Research | Bernd Steiger, Lee Wilson |

Using intelligent neuroprostheses to treat motor disorders Neurostimulation is reaching new heights: using artificial intelligence, neuroprosthetics implanted in the brain will learn to revive motor functions. |

Quebec | Quebec, Health, education and social services, Biological Systems and Functions, Mathematics and Statistics, Discovery Research | Marco Bonizzato, Marina Martinez, Numa Dancause, Guillaume Lajoie |

New UBC water treatment zaps “forever chemicals” for good Engineers at the University of British Columbia have developed a new water treatment that removes “forever chemicals” from drinking water safely, efficiently – and for good. |

British Columbia | British Columbia, Water, Civil, Industrial and Systems Engineering, Discovery Research | Madjid Mohseni |

Connecting Canada and Europe through quantum satellite communication NSERC plays an important role in Canada’s National Quantum Strategy (NQS) by supporting the advancement of research, innovation and talent development in quantum science and technology through various funding opportunities. |

Ontario, Quebec | Ontario, Quebec, Information and communication services, Physics, Research Partnerships | Thomas Jennewein |

Delving into past marine life to better comprehend modern climate issues Dr. Hilary Corlett is an assistant professor of paleontology at Memorial University of Newfoundland and Labrador. As an early-career researcher, she studies rocks that contain fossils of ancient marine life to understand the impacts of climate change at different times on Earth and learn more about the climate challenges we face today. |

Newfoundland and Labrador | Newfoundland and Labrador, Advancement of knowledge, Geosciences, Discovery Research | Hilary Corlett |

AI used to discover clean energy materials 'faster and more efficiently' Researchers at the University of Toronto have developed a method of harnessing artificial intelligence to discover new and more efficient materials for clean energy technology. |

Ontario | Ontario, Energy resources, Chemistry, Discovery Research | Alex Voznyy |

Mapping the health of kelp forests A new research alliance at the University of Victoria is examining the resilience and decline of bull kelp along the BC central coast due to warming ocean temperatures, in hopes of identifying areas of potential protection and possible restoration. |

British Columbia | British Columbia, Environment, Geosciences, Research Partnerships | Maycira Costa |

Dalhousie researchers' chance discovery could help extend battery life by replacing tape that causes self‑discharge Self-discharge of lithium-ion battery cells has frustrated users and industry alike, and puzzled manufacturers. |

Nova Scotia | Nova Scotia, Energy resources, Physics, Research Partnerships | Michael Metzger |

Rotten meat could be easier to detect thanks to a new biosensor system developed at Concordia To improve food safety, a group of Concordia researchers designed a new, inexpensive, reliable and consumer-friendly technology that identifies the presence of the toxin putrescine in beef. |

Quebec | Quebec, Advancement of knowledge, Electrical and Computer Engineering, Research Training and Talent Development | Alaa Selim, James Perry, Mohamed Nasr, Jay Pimprikar, Steve Shih |

Tiny patch would give diabetics painless glucose monitoring University of Waterloo researchers are developing a new patch that would offer diabetics an affordable, accurate, pain-free, round-the-clock alternative to traditional tests that require pricking a finger for a blood sample every few hours. |

Ontario | Ontario, Health, education and social services, Electrical and Computer Engineering, Discovery Research | Peyman GhavamiNejad, Mahla Poudineh |

The University of British Columbia and Wet’suwet’en First Nation collaborate to create new packaging foam from wood waste A new biodegradable packing foam developed at the University of British Columbia (UBC) not only potentially addresses the world’s plastic pollution crisis but also serves as an equal and true partnership example of working with First Nations. |

British Columbia | British Columbia, Manufacturing processes and products, Materials and Chemical Engineering, Discovery Research | Feng Jiang, Yeling Zhu |

An extrasolar world covered in water? With the help of instruments designed partly in Canada, a team of Université de Montréal (UdeM) astronomers have discovered an exoplanet that could be completely covered in water. |

Ontario, Quebec | Ontario, Quebec, Advancement of knowledge, Physics, Discovery Research | Charles Cadieux, René Doyon, Étienne Artigau, Neil Cook, Farbod Jahandar, Thomas Vandal, Mykhaylo Plotnykov, Diana Valencia, Nicolas B. Cowan, Björn Benneke, Stefan Pelletier, Antoine Darveau-Bernier, Ryan Cloutier, |

Aki Kikinomakaywin: opportunities in STEM for First Nation youth in northern Ontario Born out of the NORDIK Institute in Sault Ste. Marie, Aki Kikinomakaywin (formerly titled Indigenous Youth Environmental Monitoring Initiative [IYEMI]) supports the First Nation youth of northern Ontario in gaining confidence in accessing postsecondary education opportunities in STEM fields. |

Ontario | Ontario, Science promotion, Science Promotion, Research Training and Talent Development | Haley MacLeod, Susan Chiblow |

Towards an equitable, diverse, inclusive and accessible research ecosystem Dr. Wolbring is a tenured full professor at the University of Calgary’s Cumming School of Medicine in the community rehabilitation and disability studies program, who initially trained as a biochemist. |

Alberta | Alberta, Health, education and social services, Biological Systems and Functions, Research Training and Talent Development | Gregor Wolbring |

Systemic racism alters wildlife genetic diversity, University of Manitoba study reports Racist segregation housing practices in the United States of America have had a genetic impact on urban wildlife, a new study by University of Manitoba (UM) in the Proceedings of the National Academy of Sciences reports. |

Manitoba | Manitoba, Advancement of knowledge, Evolution and Ecology, Discovery Research | Colin Garroway, Chloé Schmidt |

PromoScience award supports successful initiative The University of Calgary’s Edward Johnson and Sue Arlidge have a long history of research and STEM education in the Stoney Nakoda Nation territory, in the mountains west of Calgary. |

Alberta | Alberta, Science promotion, Science Promotion, Research Training and Talent Development | Edward Johnson, Sue Arlidge |

Lenore Fahrig - Gerhard Herzberg Canada Gold Medal The proven impact of small, creative answers to big environmental problems is what drives Prof. Lenore Fahrig to inspire new thinking about how we can balance humans needs and infrastructure with better conditions for wildlife around the world. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research, Prizes | Lenore Fahrig |

Tomislav Friščić - NSERC John C. Polanyi Award Solvents account for a significant proportion of waste in chemical-based industries and their elimination remains one of the holy grails of sustainable chemistry. |

Quebec | Quebec, Advancement of knowledge, Chemistry, Discovery Research, Prizes | Tomislav Friščić |

CHIME team - Brockhouse Canada Prize This powerful collaboration of experts has designed and built one of the most novel and extraordinarily powerful radio telescopes in the world. |

British Columbia, Ontario, Quebec | British Columbia, Ontario, Quebec, Advancement of knowledge, Physics, Discovery Research, Prizes | |

Kerry Rowe - NSERC Donna Strickland Prize Dr. Kerry Rowe is a pioneer of geoenvironmental engineering who has single-handedly transformed the knowledge foundation of landfill barrier systems around the world. |

Ontario | Ontario, Environment, Civil, Industrial and Systems Engineering, Discovery Research, Prizes, Research Partnerships | Kerry Rowe |

Cynthia Goh - Synergy Award for Innovation The thriving partnership between Dr. Cynthia Goh and Vive Crop Protection has resulted in breakthrough science that has enabled the precision delivery of pesticides to enhance production while reducing environmental impact. |

Ontario | Ontario, Agriculture and primary food production, Chemistry, Prizes, Research Partnerships | Cynthia Goh |

Bala Venkatesh - Synergy Award for Innovation With nearly half of Ontarians now living in the Greater Toronto Area, providing reliable electricity is becoming increasingly complex. |

Ontario | Ontario, Energy resources, Electrical and Computer Engineering, Prizes, Research Partnerships | Bala Venkatesh |

Pierre Blanchet - Synergy Award for Innovation Professor Pierre Blanchet is considered the foremost innovator in Canada’s wood-construction industry. |

Quebec | Quebec, Manufacturing processes and products, Civil, Industrial and Systems Engineering, Prizes, Research Partnerships | Pierre Blanchet |

Norman Zhou - Synergy Award for Innovation Dr. Norman Zhou’s collaboration with Huys, Dofasco and the International Zinc Association has resulted in enhanced joining processes, novel welding consumables and equipment, and stronger lightweight materials that have allowed automotive manufacturers to meet increasingly stringent fuel economy and emission targets. |

Ontario | Ontario, Manufacturing processes and products, Materials and Chemical Engineering, Prizes, Research Partnerships | Norman Zhou |

Nathalie Méthot - Synergy Award for Innovation In 2015, when RISEHoP, a start-up firm looking for an incubator space, approached Dr. Nathalie Méthot of the Centre for Access to Bio-Innovation Technology at Collège La Cité, she was happy to accommodate them. |

Ontario | Ontario, Agriculture and primary food production, Biological Systems and Functions, College and Community Innovation, Prizes, Research Partnerships | Nathalie Méthot |

Sonia Chiasson - Arthur B. McDonald Fellowships Dr. Sonia Chiasson leads Carleton University’s Human-Oriented Research in Usable Security (CHORUS) lab, where her team conducts research at the intersection of human-computer interaction (HCI), cybersecurity and privacy. |

Ontario | Ontario, Information and communication services, Computer Science, Discovery Research, Prizes | Sonia Chiasson |

Ebrahim Karimi - Arthur B. McDonald Fellowships Ebrahim Karimi is a record-breaking international leader in the field of structured quantum waves and manipulation. |

Ontario | Ontario, Information and communication services, Physics, Discovery Research, Prizes | Ebrahim Karimi |

Blake Richards - Arthur B. McDonald Fellowships Blake Richards’s research program exists at the intersection of neuroscience and artificial intelligence (AI), where he has made notable advances in the understanding of how learning in the real brain may relate to modern AI algorithms. |

Quebec | Quebec, Information and communication services, Biological Systems and Functions, Computer Science, Discovery Research, Prizes | Blake Richards |

Angela Schoellig - Arthur B. McDonald Fellowships Angela Schoellig is at the helm of an internationally leading research group developing learning and adaptation capabilities for mobile robots. |

Ontario | Ontario, Transportation systems and services, Computer Science, Discovery Research, Prizes | Angela Schoellig |

Stephanie Simmons - Arthur B. McDonald Fellowships As an established leader in her field, Dr. Stephanie Simmons holds the key to unleashing the power of a quantum internet. |

British Columbia | British Columbia, Information and communication services, Physics, Discovery Research, Prizes | Stephanie Simmons |

Danielle Way - Arthur B. McDonald Fellowships Dr. Danielle Way’s research focuses on the effects of changes in CO2 concentration and temperature on plant physiological processes, with the overarching goal of improving our ability to predict how food security and natural ecosystems will be altered by rising temperatures and CO2 concentrations. |

Ontario | Ontario, Natural resources, Biological Systems and Functions, Discovery Research, Prizes | Danielle Way |

Openness, interdisciplinarity and the way forward Open science principles are central to our vision, and are omnipresent throughout our strategic plan, NSERC 2030: Discovery, innovation, inclusion. |

Quebec | Quebec, Advancement of knowledge, Evolution and Ecology, Discovery Research | Timothée Poisot |

Indigenous U of G prof weaves knowledge systems in unique research on Eastern wolves The first thing University of Guelph professor Dr. Jesse Popp did when considering how to research the Eastern wolf population in Northern Ontario was to reflect on what years of relationship building with local Indigenous communities had provided. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research | Jesse Popp |

Wolastoq Education Initiative: combining science with Indigenous knowledge Located on the Tobique First Nation in New Brunswick, the Wolastoq Education Initiative (WEI) is a First Nations run not-for-profit organization, delivering programming in STEM and Indigenous culture. |

New Brunswick | New Brunswick, Science promotion, Science Promotion, Research Training and Talent Development | |

Will electric bills ever go down? Lowering electricity costs and decreasing CO2 emissions is something Dr. Adel Merabet aims to achieve through his work in renewable energy integration at Saint Mary’s University. |

Nova Scotia | Nova Scotia, Energy resources, Electrical and Computer Engineering, Discovery Research, Research Partnerships | Adel Merabet |

X-Oceans Outreach: promoting diversity both above and below sea level A dedicated team out of northeastern Nova Scotia is finding new ways to inspire the next generation of ocean conservationists. |

Nova Scotia | Nova Scotia, Science promotion, Science Promotion, Research Training and Talent Development | Regina Cozzi |

Central Coast First Nations and NIC pilot geoduck aquaculture A new research partnership is examining how to increase geoduck aquaculture on the BC Coast. |

British Columbia | British Columbia, Agriculture and primary food production, Evolution and Ecology, College and Community Innovation, Research Partnerships | Naomi Tabata, Allison Byrne, Logan Zeinert |

The Royal Canadian Institute for Science (RCIScience) The Royal Canadian Institute for Science (RCIScience) is the recipient of the NSERC Award for Science Promotion (Organization). |

Ontario | Ontario, Science promotion, Science Promotion, Research Training and Talent Development | |

High school injuries inspire engineering grad to explore biomedical solutions Portia Rayner describes her University of Alberta engineering degree as a seismic “shift in mentality.” |

Alberta | Alberta, Health, education and social services, Science Promotion, Research Training and Talent Development | Portia Rayner |

Dr. Jennifer Campos - The KITE Research Institute For her career-long contributions to the promotion of science and her commitment to expanding equity, diversity and inclusivity within STEM fields, Dr. Jennifer Campos is the recipient of the 2021 NSERC Awards for Science Promotion (Individual). |

Ontario | Ontario, Science promotion, Science Promotion, Research Training and Talent Development | Jennifer Campos |

Researchers bridge the gap between disciplines to better understand chemical reactions Though chemical reactions may be very complex, they often follow a series of elementary steps as they progress. In their work, SFU chemistry PhD student Miranda Louwerse and physics professor David Sivak found that information provided by a reaction coordinate about how a reaction is progressing precisely equals how dissipating that coordinate is. |

British Columbia | British Columbia, Energy resources, Physics, Discovery Research, Research Training and Talent Development | Miranda Louwerse, David Sivak |

Seneca researchers teach machines to help video editors Ask anyone who’s done it — video editing is time-consuming, tedious work. And with demand for new content across countless platforms higher than ever, the editor’s work is never done. |

Ontario | Ontario, Information and communication services, Computer Science, College and Community Innovation, Research Partnerships | Vida Movahedi |

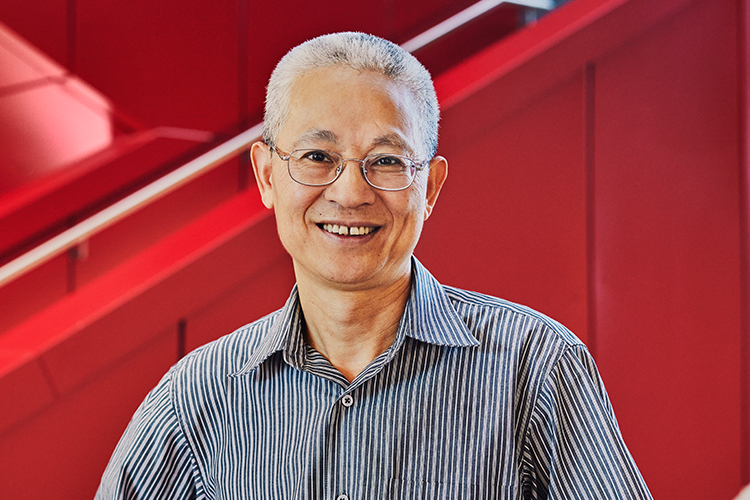

Higher education and language skills may help ward off dementia New research has found that people with mild cognitive impairment may not inevitably develop dementia and, in fact, having higher education and advanced language skills more than doubles their chances of returning to normal. |

Ontario | Ontario, Advancement of knowledge, Mathematics and Statistics, Discovery Research | Suzanne Tyas, Leilei Zeng |

Advancing research from lab to market How can we connect knowledge built in academia to people that need knowledge-based solutions for real-world challenges? In a word: innovation. But the journey from a research lab to hitting a consumer's radar is not obvious, fast, or straightforward. Transforming research discovery into new products and processes available at market usually requires investment, connections, and patience. |

Ontario | Ontario, Energy resources, Electrical and Computer Engineering, Research Partnerships | Praveen Jain |

Sheridan's Centre for Elder Research releases food security toolkit for older adults who may be at risk of social isolation When Dr. Leigh Hayden of Sheridan's Centre for Elder Research first began the proposal process for what would become the Putting Food on the Table project, she never imagined the far-reaching impact it would have for older adults in Halton. |

Ontario | Ontario, Health, education and social services, Biological Systems and Functions, College and Community Innovation, Research Partnerships | |

uOttawa study shows widespread retreat and loss of marine-terminating glaciers in the Northern Hemisphere Two researchers from the University of Ottawa are the first to map out all the glaciers that end in the ocean in the Northern Hemisphere and provide a measure of their rate of change over the last 20 years. Their findings will help better understand – and perhaps predict – the impact of climate change north of the equator. |

Ontario | Ontario, Advancement of knowledge, Geosciences, Discovery Research | Will Kochtitzky, Luke Copland |

Bioinnovation partnership leads to new, sustainable automotive material A collaboration between University of Toronto researchers and Ford Canada, led by the Faculty of Applied Science & Engineering's Professor Mohini Sain, has produced a new, sustainably-sourced, production-ready engine component for high-performance vehicles. |

Ontario | Ontario, Manufacturing processes and products, Materials and Chemical Engineering, Research Partnerships | Mohini Sain |

Keeping it tight: BETAC is ready to meet the growing need for building air tightness testing Red River College Polytechnic’s (RRC Polytech) Building Efficiency Technology Access Centre (BETAC) is providing a breath of fresh air these days. |

Manitoba | Manitoba, Construction, urban and rural planning, Materials and Chemical Engineering, College and Community Innovation, Research Partnerships | |

Catastrophizing can lead to heightened pain as measured by cardiovascular readings, Concordia research shows Our ability to manage pain varies from person to person. So what may be somewhat painful to one can be agonizing to another, even if the cause of the discomfort they are experiencing is the same. |

Quebec | Quebec, Advancement of knowledge, Genes, Cells and Molecules, Discovery Research | Geoffrey Dover, Gabriel Kakon, Amir-Arshiya Kaffash Mohamadi. Natalie Levtova, Meagane Maurice-Ventouris, Emilie-Anne Benoit, Florian Chouchou, Peter Darlington |

Ancient DNA found in soil samples reveals mammoths, Yukon wild horses survived thousands of years longer than believed Mere spoonsful of soil pulled from Canada’s permafrost are opening vast windows into ancient life in the Yukon, revealing rich new information and rewriting previous beliefs about the extinction dynamics, dates and survival of megafauna like mammoths, horses and other long-lost life forms. |

Alberta, Ontario | Alberta, Ontario, Advancement of knowledge, Evolution and Ecology, Discovery Research | Hendrik Poinar, Tyler Murchie |

Finding new life for non-recyclable rubber and plastics Now, researchers at UBC Okanagan’s School of Engineering are collaborating to develop an innovative use for non-recyclable plastic and rubber waste. In fact, these materials, mostly from cars and sporting goods, are emerging as key components in batteries and other energy storage solutions. |

British Columbia | British Columbia, Manufacturing processes and products, Materials and Chemical Engineering, Discovery Research | Amir Ahmadian, Mohammad Arjmand, Jian Liu |

Alum takes high school students under her wing Vancouver Island University (VIU) alum Samuelle Simard-Provençal led a bird banding demonstration in September 2021 to allow girls and Indigenous youth to learn about biological sciences and the different career paths they can pursue. |

British Columbia | British Columbia, Science promotion, Science Promotion, Research Training and Talent Development | Samuelle Simard-Provençal |

UM study shows most North American birds impacted by COVID-19 lockdowns UM study shows most North American birds impacted by COVID-19 lockdowns |

Manitoba | Manitoba, Environment, Evolution and Ecology, Research Partnerships | Nicola Koper |

Sajeev John - Gerhard Herzberg Canada Gold Medal Prof. Sajeev John is a world-renowned theoretical physicist whose pioneering research enables photons to be trapped and controlled in an optical microchip, analogous to how electrons are controlled in a semiconductor. |

Ontario | Ontario, Advancement of knowledge, Physics, Discovery Research, Prizes | Sajeev John |

Hanadi Sleiman - NSERC John C. Polanyi Award Breakthrough innovations developed by Prof. Hanadi Sleiman and her team at McGill University have transformed the field of DNA nanotechnology and paved the way to a revolution in medical treatments for major diseases. |

Quebec | Quebec, Advancement of knowledge, Chemistry, Discovery Research, Prizes | Hanadi Sleiman |

SOCAAR - Brockhouse Canada Prize The Southern Ontario Centre for Atmospheric Aerosol Research (SOCAAR) unites the talent of experts from engineering, environmental science, medicine, public health and government to study the sources and impacts of air pollution. |

Ontario | Ontario, Environment, Chemistry, Discovery Research, Prizes, Research Partnerships | |

Yu Sun - Synergy Award for Innovation Since 2008, Dr. Yu Sun and colleagues at the University of Toronto have partnered with Hitachi High-Technologies Canada (HTC) Inc., the country’s leading electron microscopy company. |

Ontario | Ontario, Manufacturing processes and products, Mechanical Engineering, Prizes, Research Partnerships | Yu Sun |

Bonnie Mallard - Synergy Award for Innovation Dr. Bonnie Mallard and her team at the University of Guelph have developed an innovative immunological tool well suited for the agri-food sector. |

Ontario | Ontario, Agriculture and primary food production, Genes, Cells and Molecules, Prizes, Research Partnerships | Bonnie Mallard |

Ludvik Martinu and Jolanta Klemberg-Sapieha - Synergy Award for Innovation Dr. Ludvik Martinu and Dr. Jolanta E. Klemberg-Sapieha founded the Functional Coating and Surface Engineering Laboratory (FCSEL) at Polytechnique Montréal in 1996, with a mission to collaborate with industry partners and to develop novel surface engineering processes and new specialized materials. |

Quebec | Quebec, Advancement of knowledge, Physics, Prizes, Research Partnerships | Ludvik Martinu, Jolanta Klemberg-Sapieha |

Edward Sykes - Synergy Award for Innovation Dr. Edward Sykes leads the Centre for Mobile Innovation (CMI), established at Sheridan College to create innovative solutions to health care problems in collaboration with industry and community partners. |

Ontario | Ontario, Information and communication services, Computer Science, College and Community Innovation, Prizes, Research Partnerships | Edward Sykes |

Natalie Ban - E.W.R. Steacie Memorial Fellowships Dr. Natalie Ban is a leading marine conservation scientist who mixes social and natural sciences to identify conservation priorities for coastal species and places. |

British Columbia | British Columbia, Environment, Evolution and Ecology, Discovery Research, Prizes | Natalie Ban |

Emily Cranston - E.W.R. Steacie Memorial Fellowships Dr. Emily Cranston is a world-leading nanoscientist at The University of British Columbia whose research advancements are expanding the use of nanocellulose derived from wood pulp. |

British Columbia | British Columbia, Advancement of knowledge, Materials and Chemical Engineering, Discovery Research, Prizes | Emily Cranston |

Jessica Grahn - E.W.R. Steacie Memorial Fellowships Dr. Jessica Grahn is an emerging leader studying the neuroscience of music. |

Ontario | Ontario, Advancement of knowledge, Biological Systems and Functions, Discovery Research, Prizes | Jessica Grahn |

Martin Krkosek - E.W.R. Steacie Memorial Fellowships Dr. Martin Krkosek is an expert in the field of ecology and evolutionary biology who is helping us understand and manage disease dynamics in marine fish, particularly wild and farmed salmon. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research, Prizes | Martin Krkosek |

Sandra Rehan - E.W.R. Steacie Memorial Fellowships Dr. Sandra Rehan is an international leader in the behavioural genetics and molecular ecology of bees. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research, Prizes | Sandra Rehan |

Alfred Yu - E.W.R. Steacie Memorial Fellowships Dr. Alfred Yu is guiding the direction of next-generation innovations in ultrasound technology. |

Ontario | Ontario, Manufacturing processes and products, Electrical and Computer Engineering, Discovery Research, Prizes | Alfred Yu |

UCalgary club sets the standard for digital literacy A University of Calgary club that has been lighting the coding fire in students has received national recognition. |

Alberta | Alberta, Science promotion, Science Promotion, Research Training and Talent Development | Mohammad Moshirpour |

Researchers discover unique ‘spider web’ mechanism that traps, kills viruses such as SARS-CoV-2 and influenza The researchers have found that neutrophils—the most abundant white blood cells in the human body—explode when they bind to such pathogens coated in antibodies and release DNA outside of the cell, creating a sticky tangle which acts as a trap. |

Ontario | Ontario, Advancement of knowledge, Genes, Cells and Molecules, Discovery Research | Matthew Miller, Hannah Stacey |

Rain, rain go away! SFU chemists develop new waterproofing solution A Simon Fraser University student’s experimental error in 2016 helped chemistry professor Hogan Yu and graduate student Lishen Zhang discover the waterproofing solution they were in search of. The team has now patented a coating that is cheaper, free of harmful fluorinated compounds, effective on fabric, wood, glass and metal, and superior to current consumer products. |

British Columbia | British Columbia, Manufacturing processes and products, Chemistry, Discovery Research | Hogan Yu, Lishen Zhang |

Critical research and development set to enhance mine safety and productivity A new underground wireless positioning system being developed by DICE to enhance mine safety is hoping to solve that problem. |

Saskatchewan | Saskatchewan, Natural resources, Electrical and Computer Engineering, College and Community Innovation, Research Partnerships | Terry Peckham |

Personalizing cancer treatment through machine learning Researchers at the University of Waterloo’s Cheriton School of Computer Science have applied machine learning to identify tumour-specific antigens, which could help make personalized cancer vaccines practically feasible and more accurate. |

Ontario | Ontario, Advancement of knowledge, Computer Science, Discovery Research | Hieu Tran, Ming Li |

Improving stroke treatment with a modified therapeutic molecule A research team from the Institut national de la recherche scientifique (INRS) has improved the protective effect of a molecule against ischemic stroke, which is caused by an interruption of blood flow to the brain. |

Quebec | Quebec, Advancement of knowledge, Chemistry, Discovery Research | Ahlem Zaghmi, Marc A. Gauthier |

Bilingual infants prefer baby talk Infants prefer baby talk in any language, but particularly when it’s in a language they’re hearing at home. |

Quebec | Quebec, Advancement of knowledge, Biological Systems and Functions, Discovery Research | Krista Byers-Heinlein |

Zebra finches choose nest materials based on past experience, new research shows When building a nest, previous experience raising chicks will influence the choices birds make, according to a new study by University of Alberta scientists. |

Alberta | Alberta, Advancement of knowledge, Evolution and Ecology, Discovery Research | Andrés Camacho-Alpízar, Lauren Guillette |

UBC chemist helps create new compostable coffee pod Dr. Zac Hudson believes your morning cup of coffee should be strong and guilt-free. |

British Columbia | British Columbia, Commercial services, Chemistry, Research Partnerships | Zac Hudson |

UCalgary scientists produce new canola type for potentially higher crop yield Canola is one of Canada’s most important cash crops, but there’s only so much suitable cropland where the plants can be grown. |

Alberta | Alberta, Advancement of knowledge, Biological Systems and Functions, Discovery Research | Marcus Samuel, Matija Stanic, Rex Arunraj |

Nasal spray breakthrough delivers antipsychotic drugs straight to the brain A team of neuroscientists and engineers at McMaster University has created a nasal spray to deliver antipsychotic medication directly to the brain instead of having it pass through the body. |

Ontario | Ontario, Health, education and social services, Materials and Chemical Engineering, Research Partnerships | Ram Mishra, Todd Hoare |

The bright future of infectious diseases testing When Dr. Peter Unrau of Simon Fraser University (SFU) decided to shift his academic focus from theoretical physics to molecular biology in 1996, it became abundantly clear to him that ribonucleic acid (RNA) would be an increasingly important molecule in his field. |

British Columbia | British Columbia, Health, education and social services, Genes, Cells and Molecules, Discovery Research, Research Partnerships | Peter Unrau |

Coral recovery during a prolonged heatwave offers new hope University of Victoria biologists have discovered how some corals managed to survive a globally unprecedented heatwave, in a first-ever study that provides new hope for the long-term survival of coral reefs in the face of climate change. |

British Columbia | British Columbia, Environment, Evolution and Ecology, Discovery Research, Research Training and Talent Development | Julia Baum, Danielle Claar |

Dal researchers help develop wastewater test that could act as an early warning sign for COVID-19 outbreaks Researchers at Dalhousie University have helped in the development of a rapid test to detect the presence of SARS-CoV-2 in wastewater -- an unexpected resource that is becoming a valuable sentinel in the global fight to contain the virus before it is able to spread. |

Nova Scotia | Nova Scotia, Water, Civil, Industrial and Systems Engineering, Research Partnerships | Amina Stoddart, Graham Gagnon, Rob Jamieson |

Plastics innovation spawns new building material at Sask Polytech Plastics usage, and their ability to be recycled, have come under greater scrutiny in the last few years as governments and organizations have looked to decrease our dependence on plastic. |

Saskatchewan | Saskatchewan, Manufacturing processes and products, Materials and Chemical Engineering, College and Community Innovation, Research Partnerships | Satya Panigrahi |

Chitosan: A bioplastics breakthrough “In 2020, I think we almost have a moral obligation to try to use the ingenuity, the curiosity, the immense luck we have as researchers to help with the big challenges of humanity, ” say s McGill University’s Dr. Audrey Moores. |

Quebec | Quebec, Environment, Chemistry, Discovery Research | Audrey Moores |

Molly Shoichet - Gerhard Herzberg Canada Gold Medal Although she originally considered becoming a doctor, it was a love of the lab and discovering new knowledge that ultimately inspired Molly Shoichet to focus her talents on engineering the future of medicine. |

Ontario | Ontario, Health, education and social services, Materials and Chemical Engineering, Discovery Research, Prizes | Molly Shoichet |

Karen Maxwell - NSERC John C. Polanyi Award Rising rates of antibiotic resistance threaten to topple our medical system. Chemotherapy, transplants and simple surgeries will all become impossible if we can’t prevent infections from taking hold. |

Ontario | Ontario, Advancement of knowledge, Genes, Cells and Molecules, Discovery Research, Prizes | Karen Maxwell |

José Azaña and Roberto Morandotti - Brockhouse Canada Prize Today’s computer technology is nearing the limits of its processing power, and the only solution is to move to a platform beyond electronics. |

Quebec | Quebec, Advancement of knowledge, Electrical and Computer Engineering, Discovery Research, Prizes | José Azaña, Roberto Morandotti |

NETCARE - Brockhouse Canada Prize While increased levels of greenhouse gases are the primary driving force for global warming, the roles of tiny aerosol particles—some natural and some made by humans—need to be better established to understand the complete climate system. |

British Columbia, Nova Scotia, Ontario, Quebec | British Columbia, Nova Scotia, Ontario, Quebec, Environment, Chemistry, Discovery Research, Prizes | |

Ebrahim Bagheri - Synergy Award for Innovation Ebrahim Bagheri leads a research and development team combining advanced social analytics with artificial intelligence to change the way retailers offer warranties, and change the way consumers choose the best coverage to protect their purchases. |

Ontario | Ontario, Information and communication services, Computer Science, Prizes, Research Partnerships | Ebrahim Bagheri |

Deborah Henderson and Michelle Franklin - Synergy Award for Innovation Sustainable food production is critical for our future survival on this planet, and that means balancing humanity’s needs with the health of our ecosystems. |

British Columbia | British Columbia, Agriculture and primary food production, Biological Systems and Functions, College and Community Innovation, Prizes, Research Partnerships | Deborah Henderson, Michelle Franklin |

David Eaton and Mirko van der Baan - Synergy Award for Innovation David Eaton and Mirko van der Baan helm the Microseismic Industry Consortium, a fusion of academic talent and industry expertise that is shaking up geoscientific research. |

Alberta | Alberta, Energy resources, Geosciences, Prizes, Research Partnerships | David Eaton, Mirko van der Baan |

Ali Emadi - Synergy Award for Innovation A partnership between a McMaster University research group and Fiat Chrysler Automobiles is putting electric and hybrid vehicles on the innovation fast track. |

Ontario | Ontario, Transportation systems and services, Electrical and Computer Engineering, Prizes, Research Partnerships | Ali Emadi |

William Cheung - E.W.R. Steacie Memorial Fellowships Temperature changes are having a profound impact on our oceans, forcing marine life to adapt in ways that may change ocean populations for generations. William Cheung studies the effects of climate change on marine biodiversity and fisheries. |

British Columbia | British Columbia, Environment, Evolution and Ecology, Discovery Research, Prizes | William Cheung |

Tovi Grossman - E.W.R. Steacie Memorial Fellowships Tovi Grossman sees automation as a chance for us to evolve the way we teach and learn. |

Ontario | Ontario, Information and communication services, Computer Science, Discovery Research, Prizes | Tovi Grossman |

Marc Johnson - E.W.R. Steacie Memorial Fellowships Cities are unique ecosystems full of environmental challenges not found anywhere else in nature. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research, Prizes | Marc Johnson |

Mary O'Connor - E.W.R. Steacie Memorial Fellowships Rising temperatures and waning biodiversity are reshaping ecosystems around the world. If we’re going to devise conservation efforts that support these evolving environments, we need to be able to predict the ways that ecosystems will adapt in response to climate change. |

British Columbia | British Columbia, Environment, Evolution and Ecology, Discovery Research, Prizes | Mary O'Connor |

Fanie Pelletier - E.W.R. Steacie Memorial Fellowships Until recently, most scientists thought that evolution occurred very slowly, with adaptive trait changes taking centuries. |

Quebec | Quebec, Environment, Evolution and Ecology, Discovery Research, Prizes | Fanie Pelletier |

Aiping Yu - E.W.R. Steacie Memorial Fellowships Nanotechnology is revolutionizing how we capture, store and transmit energy, but the high cost of producing carbon nanomaterials– one of the building blocks of nanotech – prevents its widespread adoption by industry. |

Ontario | Ontario, Energy resources, Materials and Chemical Engineering, Discovery Research, Prizes | Aiping Yu |

INRS researchers develop a new membraneless fuel cell The research team of INRS (Institut national de la recherche scientifique) Professor Mohamed Mohamedi has designed a green membraneless fuel cell that uses oxygen from the air. |

Quebec | Quebec, Energy resources, Chemistry, Discovery Research | Mohamed Mohamedi, Juan Carlos Abrego-Martinez, Alonso Moreno Zuria |

Some firefighting compounds harmful to aquatic life The study is the first to examine the effects on the aquatic ecosystem of the newest generation of firefighting water additives routinely used in residential and industrial firefighting. |

Ontario | Ontario, Environment, Evolution and Ecology, Discovery Research | Ryan Prosser |

The power of anti-bodies: determining COVID-19 immunity with blood testing When the University of Waterloo’s research labs shut down for quarantine, biology professor Brian Dixon pivoted some of his research away from blood testing in fish, into looking at blood testing in humans. |

Ontario | Ontario, Health, education and social services, Biological Systems and Functions, Discovery Research | Brian Dixon, Marc Aucoin |

Pathways to Graduate Studies inspires Indigenous student research For the second summer in a row, Indigenous students studying science at the University of Winnipeg were able to gain research experience and build a network with other Indigenous students |

Manitoba | Manitoba, Science promotion, Science Promotion, Research Training and Talent Development | Melanie Martin |

A highly promising sustainable battery for electric vehicles As we move to greener technologies, the need for affordable, safe and powerful batteries is constantly increasing. |

Quebec | Quebec, Energy resources, Materials and Chemical Engineering, Discovery Research | Majid Rasool |

Decades-old teeth tell the story of bottlenose whales Northern bottlenose whales live in deep waters off the coast of Nova Scotia and southern Newfoundland. An endangered species, they were targets of a century of commercial whaling across the North Atlantic. |

Nova Scotia | Nova Scotia, Advancement of knowledge, Evolution and Ecology, Research Training and Talent Development | Laura Feyrer |

UBC researchers develop biodegradable medical mask for COVID-19 Made-in-Canada design uses local wood fibres and can be produced in B.C. |

British Columbia | British Columbia, Health, education and social services, Materials and Chemical Engineering, Research Partnerships | Johan Foster, Orlando Rojas |

UVic project promotes safer, more prevalent hand washing Wash basins made with COVID-19-resistant material may be popping up in malls and other crowded places, once the work of a UVic researcher and BC manufacturer is complete. |

British Columbia | British Columbia, Manufacturing processes and products, Civil, Industrial and Systems Engineering, Research Partnerships | Rishi Gupta |

Deep fryer oil for 3D printing? Researchers at the University of Toronto Scarborough have, for the first time, turned waste cooking oil – from the deep fryers of a local McDonald’s – into a high-resolution, biodegradable 3D printing resin. |

Ontario | Ontario, Environment, Chemistry, Discovery Research | Andre Simpson |

How does COVID-19 invade our bodies so easily? In order for a COVID-19 vaccine and antiviral drugs to be developed, scientists first need to understand why this virus spreads so easily and quickly, and why it invades our bodies with seemingly little resistance from our immune system. |

Ontario | Ontario, Health, education and social services, Materials and Chemical Engineering, Research Partnerships | Milica Radisic, Axel Guenther, Edmond Young |

A vaccine of the future against COVID-19 There’s excitement in the air at the laboratory of Dr. Denis Leclerc, a professor in the Faculty of Medicine at Laval University and a researcher at Quebec City’s CHU Research Centre. |

|||

Clean energy revolution Four years ago, Queen’s University researcher Gregory Jerkiewicz and his team of Canadian and international collaborators received a competitive $4 million Discovery Frontiers grant from the Natural Sciences and Engineering Research Council of Canada (NSERC). |

Ontario | Ontario, Advancement of knowledge, Chemistry, Discovery Research | Gregory Jerkiewicz |

PermafrostNet connects a community Climate change began to show its effects, and in doing so destabilized the certainties of a generation of research. |

Ontario | Ontario, Natural resources, Geosciences, Research Partnerships | Stephan Gruber |

Student Highlights Halifax’s Women in Science Emma Finlayson-Trick didn’t think of herself as a natural scientist when she was growing up, but a few “amazing individuals” in her life inspired her to find a passion for science. |

Nova Scotia | Nova Scotia, Science promotion, Science Promotion, Research Training and Talent Development | Emma Finlayson-Trick |

Reducing phosphorus in waterways Dr. Darshani Kumaragamage is dispelling the myth that farmers and livestock producers are to blame for increased phosphorus release into waterways, leading to algae blooms in Lake Winnipeg. |

Manitoba | Manitoba, Environment, Geosciences, Discovery Research | Darshani Kumaragamage |

Improving wastewater decontamination At Concordia, with a team of 15 undergraduate, graduate and visiting researchers, Howarth focuses on the design and synthesis of rare-earth metal-organic frameworks targeting applications in wastewater remediation and chemical sensing. |

Quebec | Quebec, Environment, Chemistry, Discovery Research | Ashlee Howarth |

Water detected on an exoplanet located in its star’s habitable zone Ever since the discovery of the first exoplanet in the 1990s, astronomers have made steady progress towards finding and probing planets located in the habitable zone of their stars, where conditions can lead to the formation of liquid water and the proliferation of life. |

Quebec | Quebec, Advancement of knowledge, Physics, Discovery Research | Bjorn Benneke, Caroline Plaulet |

Self-healing gel McMaster researchers have developed a novel new gel made entirely from bacteria-killing viruses. |

Ontario | Ontario, Health, education and social services, Materials and Chemical Engineering, Discovery Research | Zeinab Hosseini-Doust |

Barbara Sherwood Lollar - Gerhard Herzberg Canada Gold Medal Barbara Sherwood Lollar’s research career has been defined by exploration and discovery. As one of Canada’s most renowned earth scientists, she has given us incredible insights about the nature of water and life on our planet. |

Ontario | Ontario, Advancement of knowledge, Geosciences | Barbara Sherwood Lollar |

Douglas Stephan - NSERC John C. Polanyi Award Just after the turn of the millennium, Douglas Stephan took a 100-year-old chemistry process and redesigned it into something cheaper, more efficient and more environmentally friendly. |

Ontario | Ontario, Manufacturing processes and products, Chemistry, Discovery Research, Prizes | Douglas Stephan |

Pascale Champagne, Michael Cunningham, Philip Jessop and Warren Mabee - Brockhouse Canada Prize If we are to achieve the dream of an environmentally sustainable future, our technologies, natural resources and industrial processes will need to be fully integrated with one another. |

Ontario | Ontario, Environment, Civil, Industrial and Systems Engineering, Discovery Research, Prizes | Pascale Champagne, Michael Cunningham, Philip Jessop, Warren Mabee |

Paul Charette - Synergy Award for Innovation Paul Charette led a team of members from Université de Sherbrooke and Polytechnique Montréal that collaborated with industry partner Teledyne DALSA to create the world’s first high-resolution infrared camera for non-military use. |

Quebec | Quebec, Information and communication services, Electrical and Computer Engineering, Discovery Research, Prizes | Paul Charette |

Luc Landry - Synergy Award for Innovation Innovative engineers from the Solutions Novika centre, based at Cégep de La Pocatière, teamed up with industry partners from Umano Medical, who have market expertise, to develop the next generation of hospital beds. |

Quebec | Quebec, Manufacturing processes and products, Electrical and Computer Engineering, College and Community Innovation, Prizes, Research Partnerships | Luc Landry |

Amar Mohanty - Synergy Award for Innovation Amar Mohanty has teamed with three Ontario-based companies to develop innovative biodegradable materials that are substitutes for petroleum-based plastics. |

Ontario | Ontario, Advancement of knowledge, Materials and Chemical Engineering, Prizes, Research Partnerships | Amar Mohanty |

Roberto Morandotti - Synergy Award for Innovation Roberto Morandotti is harnessing the power of light to take us beyond the limits of today’s digital technology. |

Quebec | Quebec, Advancement of knowledge, Electrical and Computer Engineering, Prizes, Research Partnerships | Roberto Morandotti |

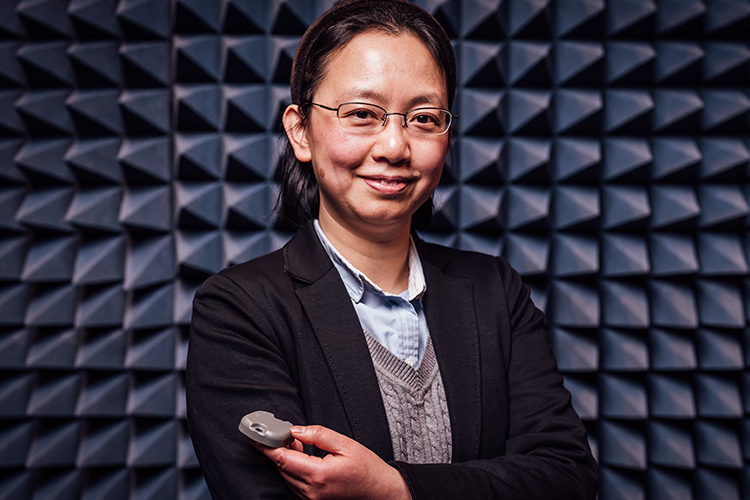

Lin Cai - E.W.R. Steacie Memorial Fellowships Wireless networks are making our lives easier every day, and Lin Cai sees the deep complexity behind them. |

British Columbia | British Columbia, Information and communication services, Electrical and Computer Engineering, Discovery Research, Prizes | Lin Cai |

Maud Ferrari - E.W.R. Steacie Memorial Fellowships Maud Ferrari wants to know how animals learn to survive in an increasingly dangerous world. Almost all organisms live in environments that have been altered, to some degree, by humans. |

Saskatchewan | Saskatchewan, Environment, Evolution and Ecology, Discovery Research, Prizes | Maud Ferrari |

Erin Johnson - E.W.R. Steacie Memorial Fellowships Erin Johnson is building better methods to describe chemistry, starting at the very foundation. |

Nova Scotia | Nova Scotia, Advancement of knowledge, Chemistry, Discovery Research, Prizes | Erin Johnson |

Paul McNicholas - E.W.R. Steacie Memorial Fellowships For Paul McNicholas, statistical analysis is a bit like being a treasure hunter. He designs the right tools to sift through massive amounts of data to reveal secrets buried within. |

Ontario | Ontario, Advancement of knowledge, Mathematics and Statistics, Discovery Research, Prizes | Paul McNicholas |

Dwight Seferos - E.W.R. Steacie Memorial Fellowships Dwight Seferos' expertise in synthetic chemistry enables him to develop new materials from novel resources, like vitamins, so he can create power-storing plastics that are safer, environmentally friendly and less expensive to manufacture. |

Ontario | Ontario, Energy resources, Chemistry, Discovery Research, Prizes | Dwight Seferos |

Hongbo Zeng - E.W.R. Steacie Memorial Fellowships Hongbo Zeng zooms down to the molecular level to understand the forces that make objects slip, grip, squeeze, slide and stick. |

Alberta | Alberta, Energy resources, Materials and Chemical Engineering, Discovery Research, Prizes | Hongbo Zeng |

Wave goodbye to user error Researchers at the University of Waterloo have developed a strategy that could reduce the level of frustration users experience when giving gesture commands to smart devices and smart environments. |

Ontario | Ontario, Information and communication services, Computer Science, Discovery Research | Edward Lank, Keiko Katsuragawa |

Big fish in a shrinking pond Populations of large fish and other marine species will decline steadily if little is done to stem the effects of climate change, according to a study led by Dalhousie University researchers that shows how greenhouse gas emissions could cause widespread global stock losses and habitat shifts. |

Quebec | Quebec, Environment, Evolution and Ecology, Discovery Research | Derek Tittensor |

Spider spinning technology When University of Victoria biomedical engineer Mohsen Akbari gets talking about the futuristic microfibres being created in his lab to solve medical mysteries, it sounds just about as far away from nature as you can get. |

British Columbia | British Columbia, Health, education and social services, Mechanical Engineering, Discovery Research | Mohsen Akbari |

Honey bees can help monitor pollution in cities Honey from urban bees can tell us how clean a city is and help pinpoint the sources of environmental pollutants such as lead, new University of British Columbia research has found. |

British Columbia | British Columbia, Advancement of knowledge, Geosciences, Discovery Research | Kate E. Smith, Dominique Weis |

The wild, wild west of wearable technology If you’re out sweating with your Fitbit aiming for 10,000 steps, Kinesiology’s Dr. Reed Ferber (English only), PhD, wants you to know you don’t need to feel guilty if you don’t hit that goal. |

Alberta | Alberta, Health, education and social services, Mechanical Engineering, Discovery Research, Research Partnerships | Reed Ferber, Lauren Benson, Nizam Ahamed, Dylan Kobsar |

Foam to Bone Researchers from the University of British Columbia and McMaster University have developed what could be the bone implant material of the future: an airy, foamlike substance that can be injected into the body and provide scaffolding for the growth of new bone. |

British Columbia, Ontario | British Columbia, Ontario, Advancement of knowledge, Materials and Chemical Engineering, Discovery Research, Research Training and Talent Development | Daniel Osorio, Emily Cranston, Kathryn Grandfield |

Partnership connects students to their waterways and communities A unique project focused on helping School District 91 students in the Nechako watershed region become more connected to their waterways and communities has launched in Vanderhoof, British Columbia. |

British Columbia | British Columbia, Science promotion, Science Promotion, Research Training and Talent Development | Margot Parkes |

A groove is better with rhythm and harmony, new research shows It takes King Curtis less than half a minute into “Memphis Soul Stew,” his best-remembered song, to really get a groove going. When it does, it doesn’t let go. |

Quebec | Quebec, Advancement of knowledge, Biological Systems and Functions, Discovery Research | Tomas Matthews |

Grape Balls of Fire Trent University professor Dr. Aaron Slepkov worked with seven undergraduate students to answer the question of why microwaved grapes become a fireball light show. |

Ontario, Quebec | Ontario, Quebec, Advancement of knowledge, Physics, Discovery Research, Research Training and Talent Development | Aaron Slepkov, Pablo Bianucci |

University research partnership forms new company Dr. Maev, Institute for Diagnostic Imaging Research (IDIR) and local ultrasonic imaging manufacturer Tessonics Inc., has developed a new way of applying powder coatings that cleans, coats, and works metal in a single operation. |

Ontario | Ontario, Construction, urban and rural planning, Materials and Chemical Engineering, Research Partnerships | Roman Maev |

The “grandmother effect”: a crucial role in demographic evolution From a biological perspective, menopause in women is puzzling: in comparison to what is observed in other species, it occurs much earlier, and long before the end of women’s life expectancy. |

|||

Creating cocrystals from deep in the periodic table Imagine a waterproof computer. It’s not going to happen tomorrow, but it may no longer be a pipedream since a McGill-led international research team has shown for the first time that it is possible to form strong, stable attractions between some of the heavier elements in the periodic table. |

|||

Amateur hockey with a professional twist Researchers at York University have developed a deep learning-based computer vision system for attentive puck tracking (APT) that is able to automatically track the play in a game of hockey and deliver a dynamic zoomed video feed similar to an NHL broadcast feed. |

Ontario | Ontario, Information and communication services, Computer Science, Research Partnerships | Hemanth Pidaparthy, James Elder |

CCOVI research vineyards to tackle climate change challenges Brock University’s Cool Climate Oenology and Viticulture Institute (CCOVI) is looking to aid Canada’s grape growers and wineries with the help of two new research vineyards. |

Ontario | Ontario, Agriculture and primary food production, Biological Systems and Functions, Research Partnerships | Jim Willwerth, Debbie Inglis |